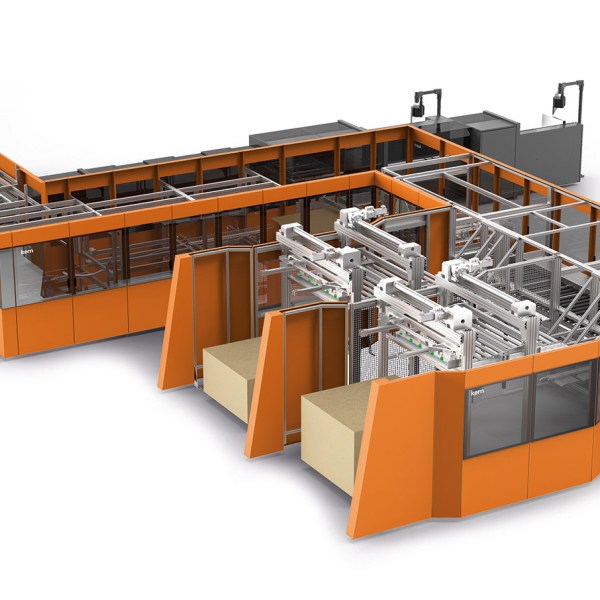

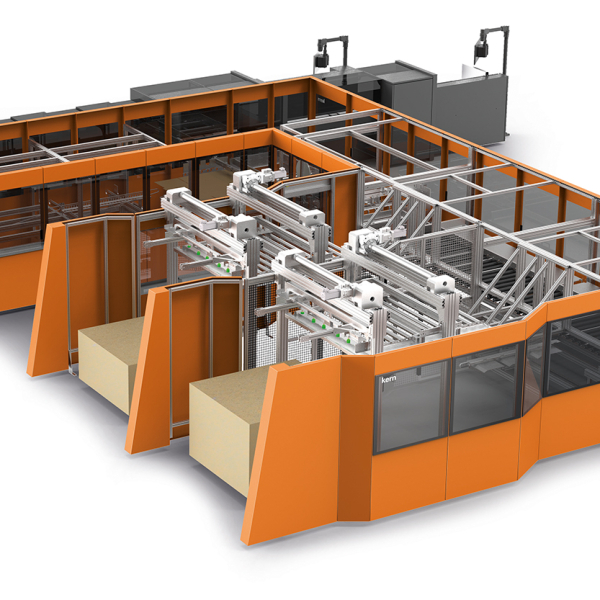

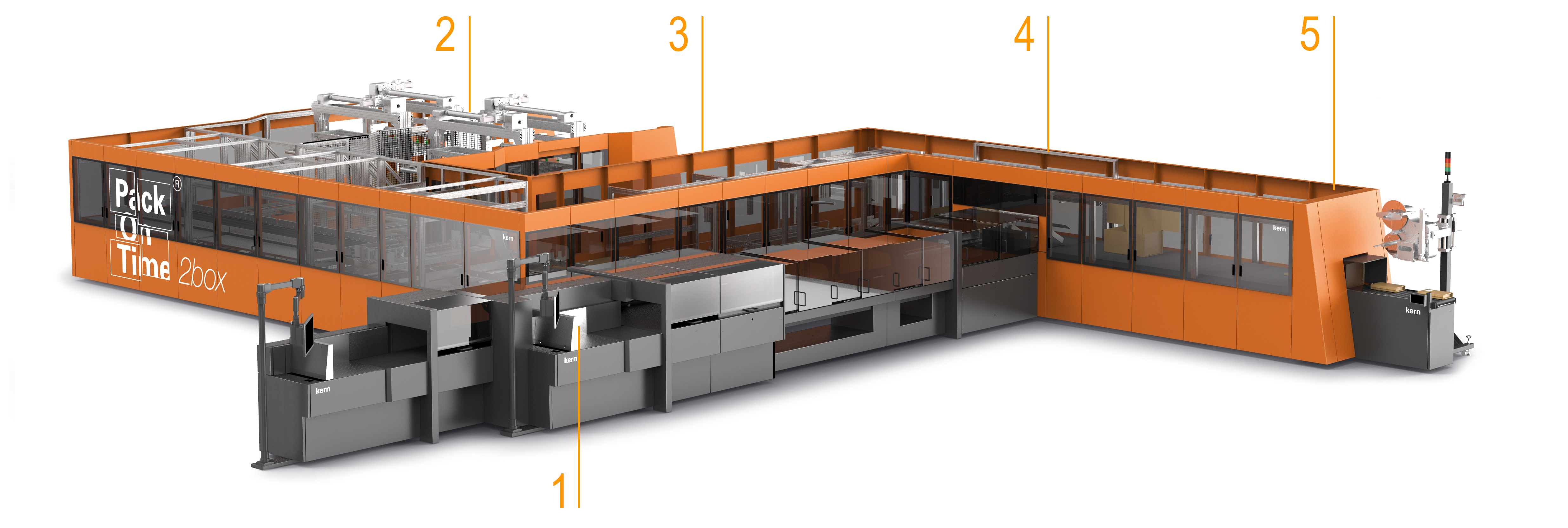

1 Item placement and measurement

The items are placed on a belt and fed to the system. The dimensions of the placed items are measured to determine the required box size. Depending on the requirements, the system can be equipped with multiple inserting stations.

2 Corrugated cardboard sheet feeder

The box is made from corrugated cardboard sheets. Depending on the determined dimensions, the system selects the appropriate cardboard size. The system can be equipped with up to three corrugated cardboard sheet feeders according to the requirements.

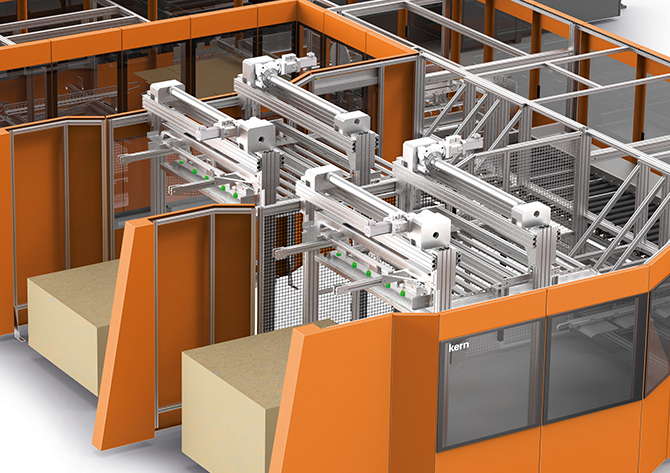

3 Corrugated cardboard processing

The corrugated cardboard is tailor cut in a first step then perforated and creased. The box is partially erected, glued, and transported to the items infeed station.

4 Items insertion

The system conveys the items into the tailor-made box. Before closing a delivery note or invoice can be inserted into the box.

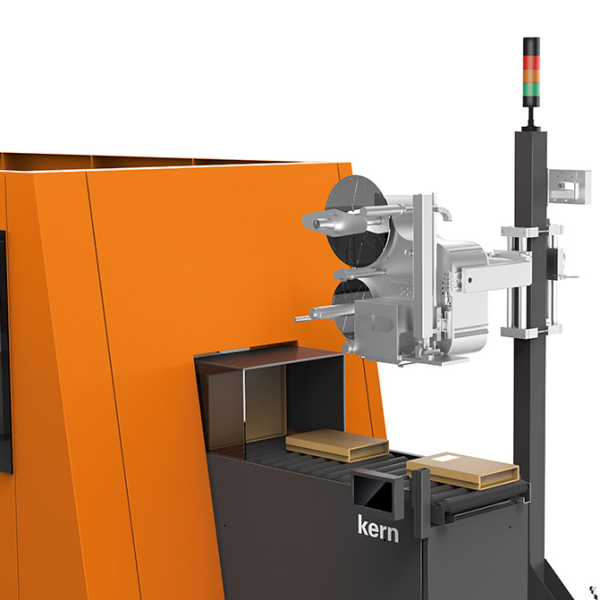

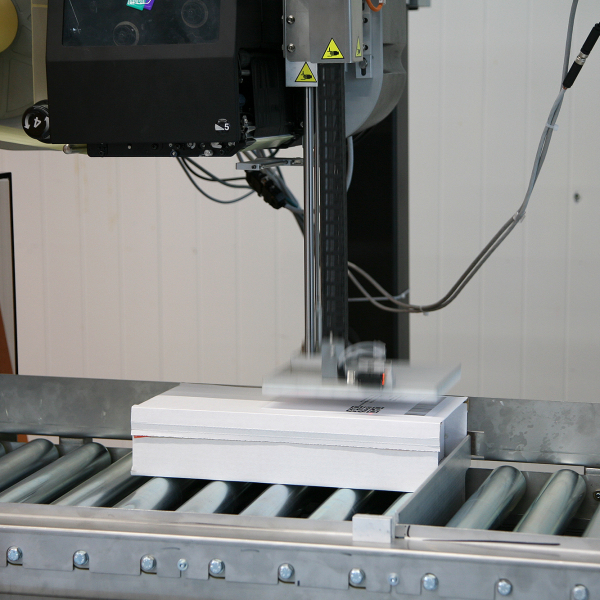

5 Closing and labelling

The box is now automatically closed and sealed. Before leaving the system, the package will be provided with the corresponding shipping label.

PackOnTime 2box - Brochure

9 MB

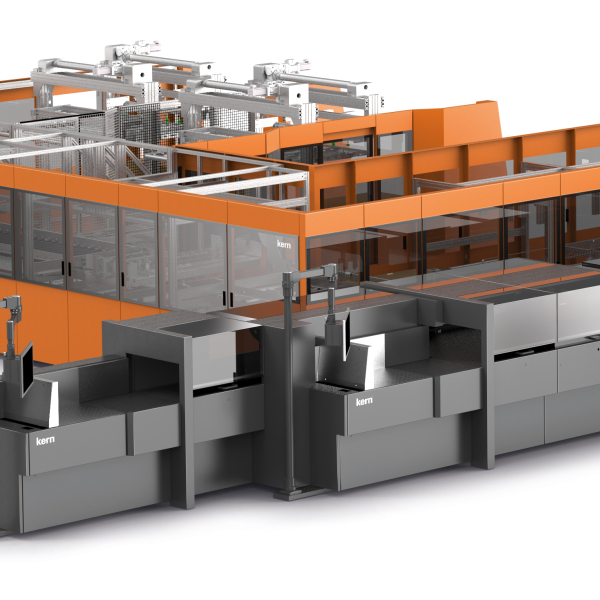

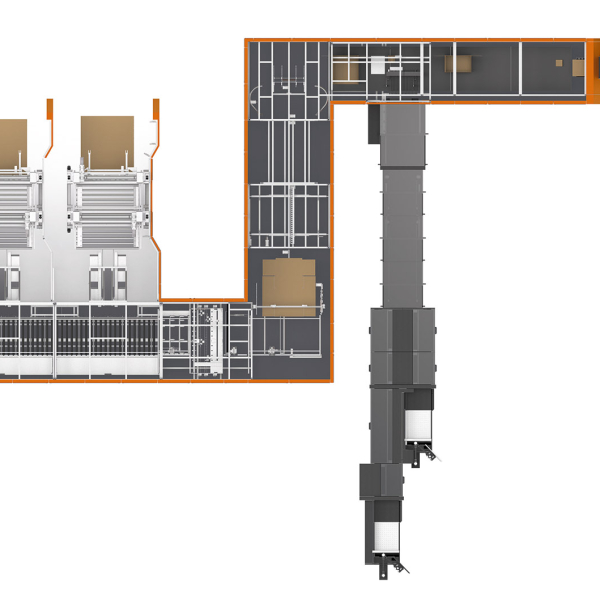

Multi Format Packaging System. Tailor-made packages – quick and easy.

PackOnTime 2box

Facts at a glance

- Operation:

by 1 person - Package size (inner dimensions):

min. 100 × 150 × 50 mm

max. 600 × 400 × 300 mm - Package weight:

up to 20 kg - Corrugated cardboard sheets:

Recommended B-wave 3 mm

fed from pallet:

stack height 1.5 m (approx. 450 sheets) - Closure:

hot glue - System dimensions

(basic configuration):

10 × 16 × 2 m

Our Services

- Personal consultancy on-site

- Requirement analysis, and solution proposal according to customer needs

- Installation by Kern AG

- System integration

- On-site training of your employees

- Reliable support and maintenance during operation

- Customer-oriented service models