The patented shape of the corrugated cardboard box enables securely transport of content, space-saving storage, and simple handling during sorting and stacking.

The booming online market generates a higher demand for paper and corrugated cardboard packaging. Corrugated cardboard is popular because it requires, when folded, little space, and despite its relatively low weight, provides good stability and protection of the packaged goods. Corrugated cardboard is also environmentally meaningful because it is mainly manufactured from recycled paper.

Up to now, large quantities of identical boxes had to be produced to keep the cost of corrugated cardboard boxes low. Each change of the box size generates setup costs for box production, and time-consuming adjustments on the packaging machines. The consequence is a high ratio of air which must be transported, stored, and transshipped. Very often this empty space is filled with auxiliary materials such as polystyrene chips or wood wool, causing additional handling by the recipient.

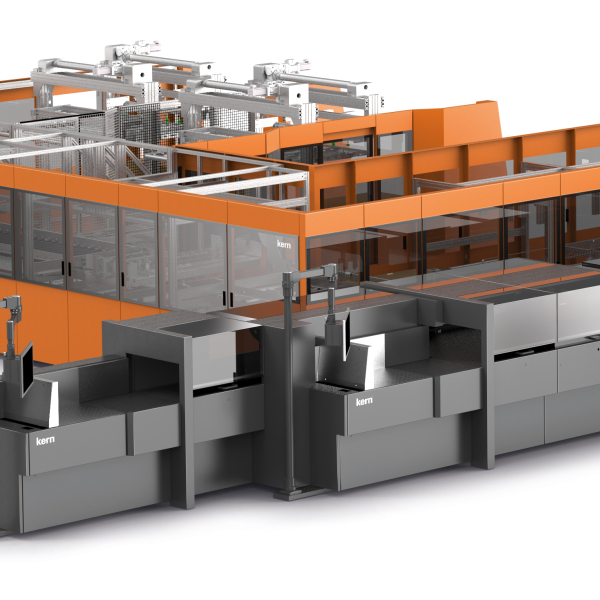

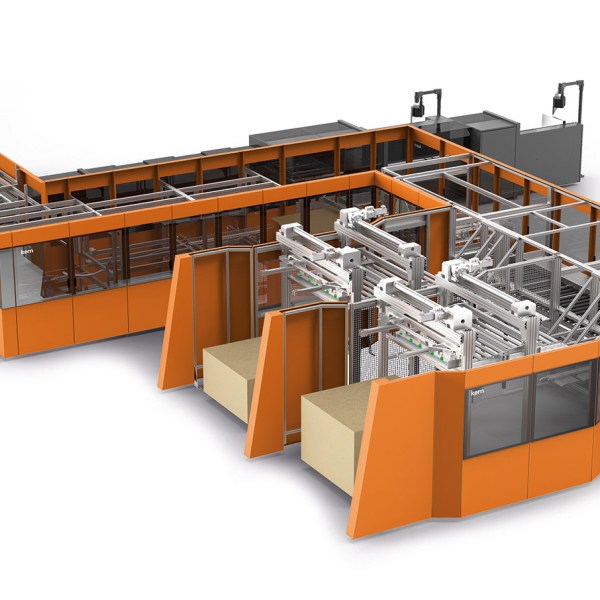

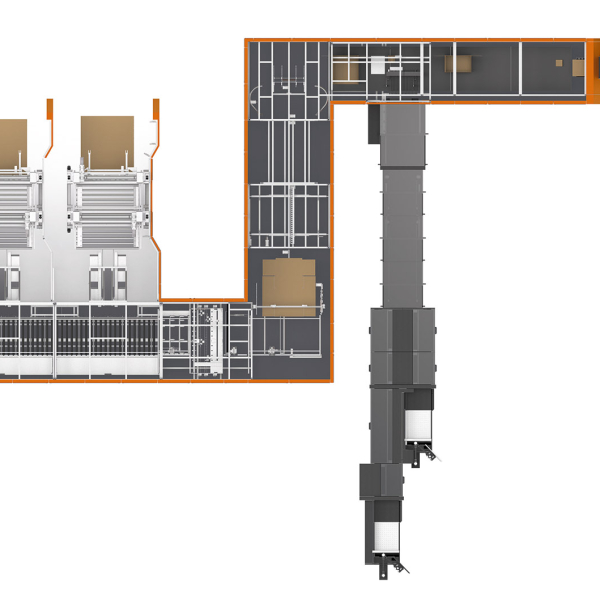

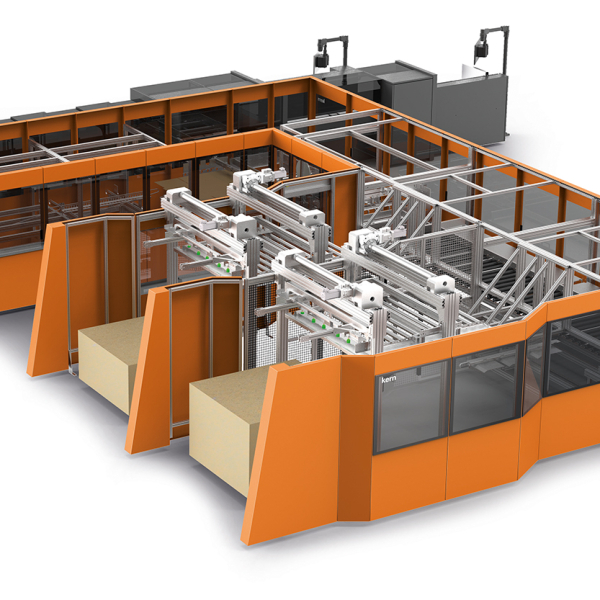

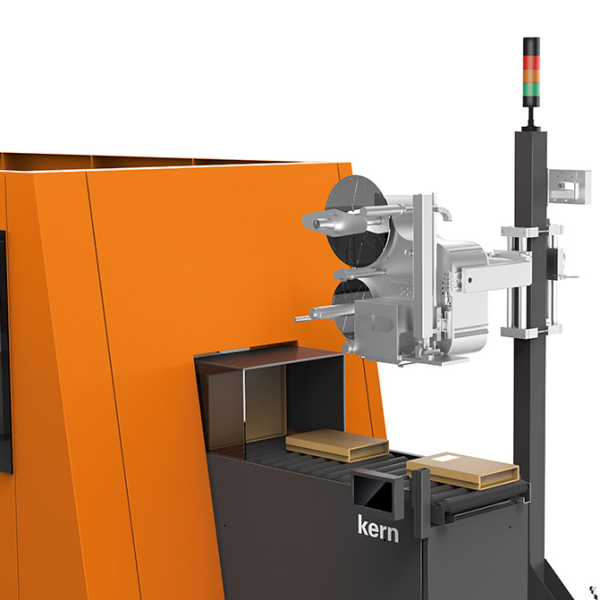

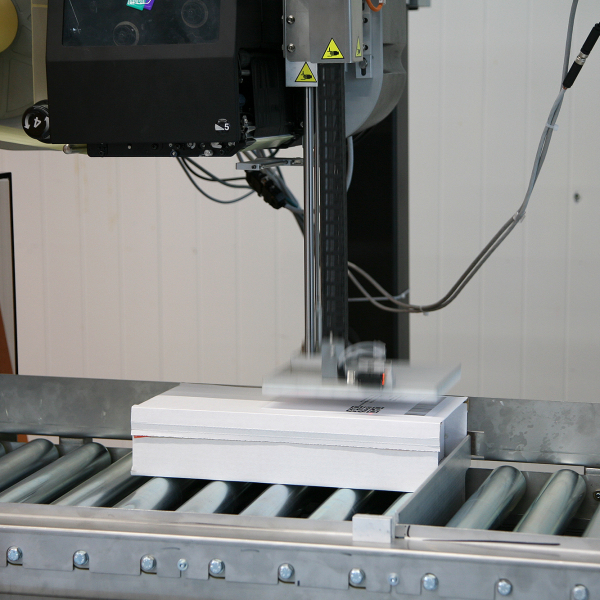

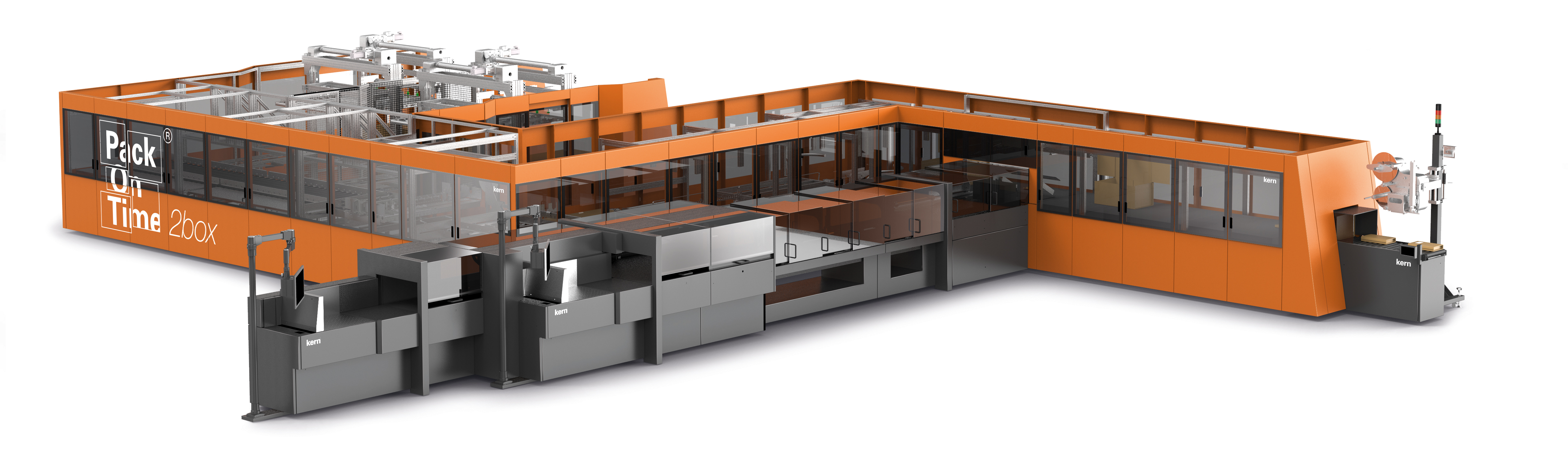

PackOnTime 2box produces boxes from corrugated cardboard sheets at the optimal size for each type of order. The goods are well protected against damage on the dispatch route, without additional filling material. To produce the appropriate box size, the items to be packed are measured dynamically, then automatically packed and the box sealed. The result is a significant reduction of package volume. A valuable contribution to environmental protection.

Thanks to an integrated tear-off-strip the package can be opened frustration free, without any tools. The stable shape of the box allows return shipment as well as the use for storage.

When opening the package, you get an impression of high quality and the content is nicely presented. The boxes can be branded as desired by using preprinted cardboard sheets, or by adding a digital printer. The use of corrugated cardboard sheets allows fast and simple changeover between various cardboards.

PackOnTime 2box - Brochure

9 MB

Multi Format Packaging System. Tailor-made packages – quick and easy.

PackOnTime 2box

Brief overview

The tailor-made box fulfils the most important criteria for secure shipment of the ordered items:

- The dimensionally stable box provides optimal content protection during transport.

- The patented shape encloses the content, with no need for additional filling material.

- Box made from environmentally friendly material (cardboard).

- Stress-free opening of package, without tools.

- Box can easily be reused for returns.

- Box design leads to an attractive presentation of content after opening.

Our Services

- Personal consultancy on-site

- Requirement analysis, and solution proposal according to customer needs

- Installation by Kern AG

- System integration

- On-site training of your employees

- Reliable support and maintenance during operation

- Customer-oriented service models